In 2022, with the increasing integration of large-scale, professional and international production, POMA continuously adheres to its beliefs in the research & development and production of thermal transfer ribbons and strives to become a leading international labeling service provider.

An agent based in Jiangsu provides a large-scale medical printing effect application and received a good reputation from its end users.

The bid winning this time fully reflects POMA's powerful business strength and top-grade service level, further proves POMA's competitiveness in the same industry and lays a solid foundation for POMA to expand the market. We will continuously provide perfect answers to agents in various regions around the world with guaranteed quality, quantity and timeliness.

During the epidemic period, POMA collaborated with a regional dealer to find large medical clients and was successfully shortlisted in national large-scale bidding, with the ribbon model of POMA UR370. A medical client used industrial grade barcode output equipment, such as Z^^BA's Z^410, Z^510 and 110^4(600dpi), and required efficient and high-quality thermal transfer ribbons. Its requirements are as follows:

1. Alcohol, xylene, paraffin (60 ℃) and decalcification solution are commonly-used reagents.

2. In actual use, reagents possibly used include: acetone, glycerol, dioxane, n-butanol + ethanol aqueous solution, tert-butanol, chloroform, aniline oil, etc. Each hospital might use slightly different reagents and 1-2 types of processes might be added.

3. It is required that labels should be printed at a low temperature and output at a high speed, the label contents should have high text clarity without white dots and there is no obvious damage to the printing head to effectively extend its lifespan for a long time.

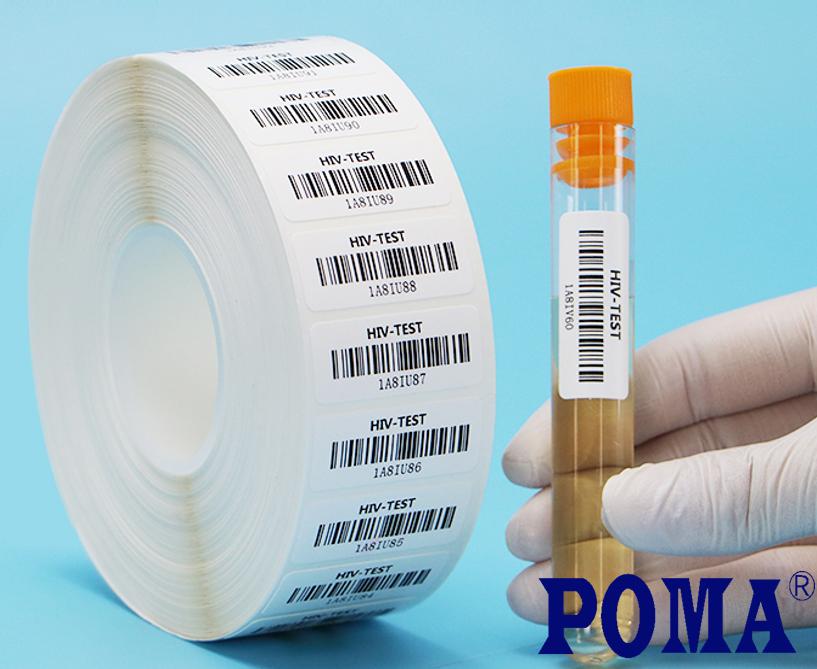

Pictures of POMA's thermal transfer ribbons and label applications:

|

|

|

Medical industry |

|

Customer Background |

|

The 21st century has seen unprecedented medical advancements, which are constantly changing the way we diagnose, manage and treat diseases. However, change doesn't mean no challenges. In laboratories and complex hospitals, the rapidly-increasing sample size has placed higher demands on the way you label, track and report samples. |

|

|

|

|

|

Opportunities and Challenges |

|

Manual labeling may lead to loss or misreading of information. ★ Illegible ★ Possible ink halo ★ Limited writing space ★ Gradual fading during storage ★ Easily erased by chemicals |

|

|

|

Medical industry |

|

Application Plan |

|

The combination of top-grade ribbons and labels may provide clear and legible information. ★ Clear and legible ★ No ink halo or fainting ★ A large amount of information possibly contained in a barcode ★ Durability and chemical resistance |

|

|

|

|

|

Key Success Factors |

ü POMA UR370 is a newly developed high-density resin ribbon, which can be used by near edge and flat head printers. UR370 resin ribbon is widely used for special labels and its printed ink has strong stain resistance and scratch resistance. With high density printing, it can achieve excellent results when printing small barcode text and labels. It is also characterized in alcohol resistance, corrosion resistance, high temperature resistance (250 ℃), powerful stain resistance and low temperature storage endurance (-20 ℃). It is suitable for customers to print small and thin fonts and barcodes on the site and for large group users worldwide to use multiple label types. It is also a preferred choice for high-speed and low-temperature printing. ü Its printing speed ranges from 100mm/s (4 in) to 254mm/s (10 in) and its printing temperature range is desirable (taking the brand barcode printer ZE^2 with a high market share as an example, the temperature between 22 and 24 can effectively extend the lifespan of the printing head). ü The printing temperature requirement of POMA resin ribbon UR370 (including UR310, UR330, UR350 and UR360) is at least 30% lower than that of industrial competitors. So, it can effectively extend the lifespan of and protect the printing heads of the customers. ü On the printer end with the same parameter configuration, the noise of POMA ribbon is 40% lower than that of the competitors, so that it is possible to effectively avoid environmental pollution in occupational diseases. ü During continuous printing for a long time in the printing room, the smell emitted by POMA ribbon is minimal, lighter than the ink smell of the competitor ribbons. ü POMA resin ribbons can also be used for printing on dyed coated paper. So, they are superior to other brands and it is more adaptable and flexible in label materials. |

|

With rich practical application experience and long-term business cooperation with many well-known domestic and foreign enterprises,

We, POMA People, believe that we can bring you more professional experience and value.